- #Servo motor arduino wires serial

- #Servo motor arduino wires drivers

- #Servo motor arduino wires update

- #Servo motor arduino wires full

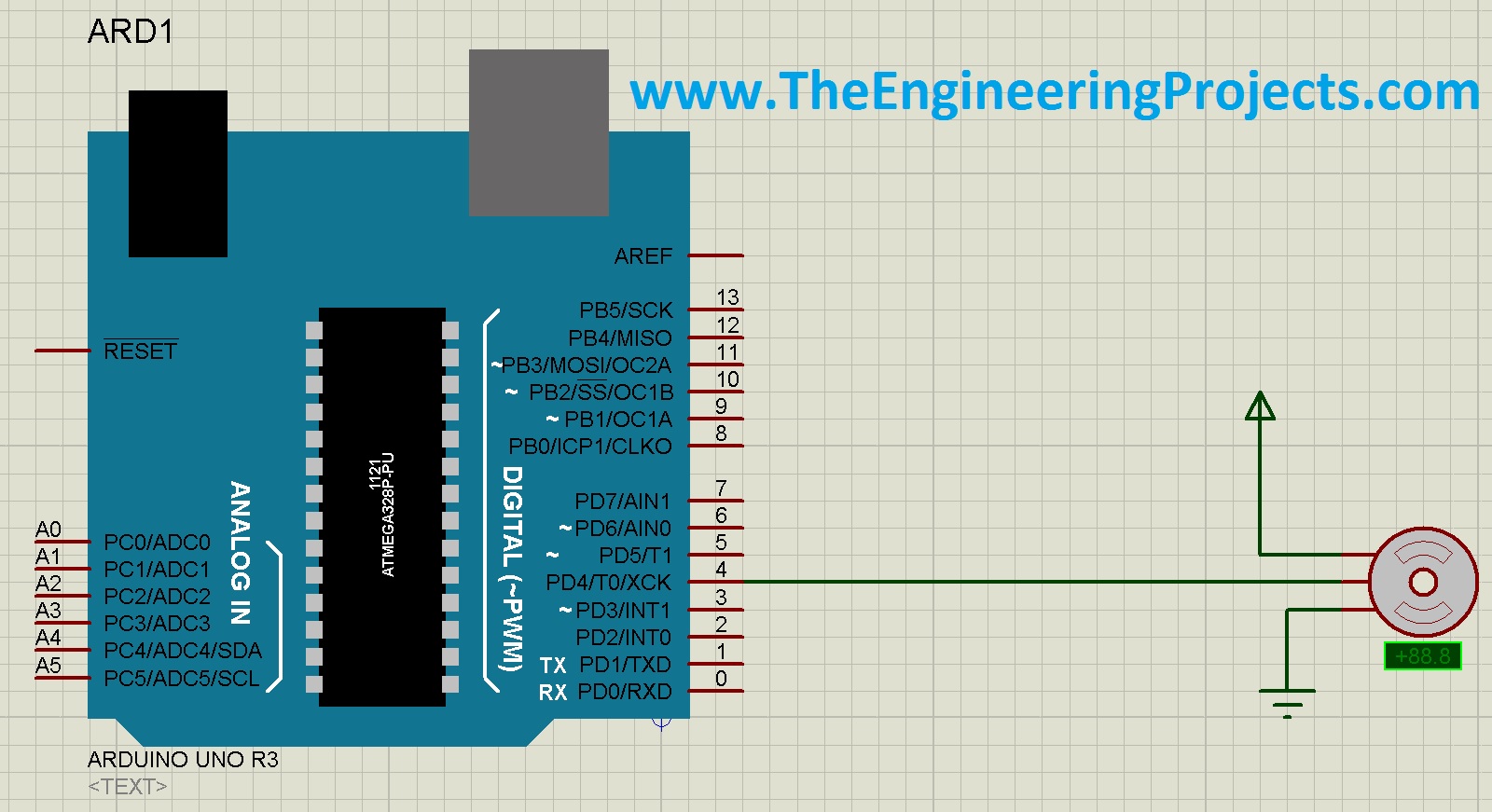

Now connect Servo control Pin at respective Pin and provide supply to it. When sketch is Uploaded, Press Reset on the board. After verifying it will notify if there are any errors otherwise ‘Done Compiling’ will be shown. Write the code and ‘verify’ (option on toolbar) it. Open Arduino IDE and Create a new Sketch (In Arduino world code/program is called a ‘sketch’).

#Servo motor arduino wires drivers

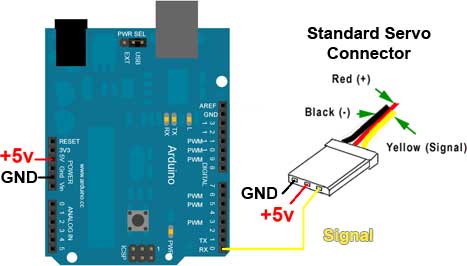

On connecting the board first time, it’ll ask for the drivers (which can be downloaded from arduino website). Connect USB with PC and upload the sketch to the board. Orange Wire: PWM output from pin9 to Motor Control InputĬonnect the Supply to the board (5-12V DC).

It communicates using the original STK500 protocol. The ATmega2560 on the Arduino Mega comes preburned with a bootloader that allows you to upload new code to it without the use of an external hardware programmer. Each pin can provide or receive a maximum of 40 mA and has an internal pull-up resistor (disconnected by default) of 20-50 kOhms.

#Servo motor arduino wires update

The Mega 2560 is an update to the Arduino Mega, which it replaces.Įach of the 54 digital pins on the Mega can be used as an input or output, using pinMode(), digitalWrite(), and digitalRead() functions. The Mega is compatible with most shields designed for the Arduino Duemilanove or Diecimila.

It contains everything needed to support the microcontroller simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started.

#Servo motor arduino wires serial

It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs(hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button. The Arduino Mega 2560 is a microcontroller board based on the ATmega2560. 3: Typical Image of Servo Motor Arduino Mega2560įig. It can rotate 0-180 degrees at a maximum speed of 2.2msec/180deg.įig. Say at 4.8-5V it can give up to 14-15 Kg-cm. However this torque varies with supply voltage. The servo motor used here has 17 Kg-cm torque (This is its max. This article is about interfacing a servo motor with Arduino Mega series board. Also, a servo operation is vibration-less and is free of resonance issues. Sometimes a servo can provide up to twice its rated torque for short duration. It can maintain 90%of its rated torque at high speed. Servo motor is used because it is easy to operate (PWM technique).

In that case, check if you can set your servo controller to custom pulse lengths and try 0.75ms to 2.25ms.Servo motor is widely used by engineers and hobbyists in various applications.

#Servo motor arduino wires full

Note that the default servo pulse widths (usually 1ms to 2ms) may not give you a full 180 degrees of motion. Position "0" (1.5ms pulse) is middle, "90" (~2ms pulse) is all the way to the right, "-90" (~1ms pulse) is all the way to the left. To control with an Arduino, we suggest connecting the orange control wire to pin 9 or 10 and using the Servo library included with the Arduino IDE ( see here for an example sketch). We now carry the Tower-Pro MG-995, they are very nice, high-quality servos, excellent for use in robotics. Comes with a bunch of plastic horns, as shown. Be careful not to use power supply greater than the motor voltage, since the operating voltage is. The following circuit show how you should connect Arduino to PCA9685 module. This module can control a large number of servo motors at the same time. Good for beginners who want to make stuff move without building a motor controller with feedback & gearbox. The most important application is to control servo motors. You can use any servo code, hardware, or library to control these servos. This high-torque standard servo now comes in a metal-gear flavor, for extra-high torque (10 kg*cm!) and reliability! It can rotate at least 120 degrees (60 in each direction) with a classic 1.5-2.5ms pulse, but if you can extend your pulses it can go up to about 170 degrees - it varies a bit servo-to-servo.

0 kommentar(er)

0 kommentar(er)